8

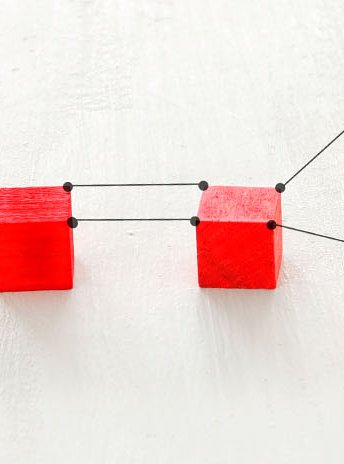

Eight workstations and individual machining consisting of micromotor, work box, automatic suction and extraction system.

4

Four workstations in the impression-taking area with specific instruments per student

The Machining Laboratory is part of the modern facilities offered in Universidad Europea de Madrid’s Faculty of Biomedical and Health Sciences, and has been designed as a state-of-the-art space for learning the manufacturing process of an adapter mould, a customised hearing aid or even a hearing protector.

In this laboratory students will carry out the production process of an adapter mould, a custom-made hearing aid or even a hearing protector in all its variations and using different materials. This process will be performed in its entirety, starting from the impressions of the patient's ear to the final fitting of the prosthesis.

The laboratory is equipped with the latest technology in the manufacturing of hearing aids, using the photopolymerisation and vulcanisation methods. It also features safety measures for each procedure in its facilities, imitating a real production laboratory.

This laboratory trains students in the Advanced Technician in Prosthetic Audiology qualification over a two year period. Here they will develop the professional skills required in an audiology office, as well as the skills used in modelling, machining and quality control of hearing aid production laboratories.

These facilities have a multitude of technological learning systems, including the following:

- 8 work and individual machining stations consisting of a micro motor, work box, an automatic vacuum and an extraction system.

- Extraction hood for hearing aid lacquering.

- UV Light Guns

- Pressuriser for the production of soft moulds

- 3D printing scanner with specific IT support

- 4 workstations for taking impressions equipped with the specific instruments for each student

- UV polymerisation machine for the creation of moulds and for lacquering.