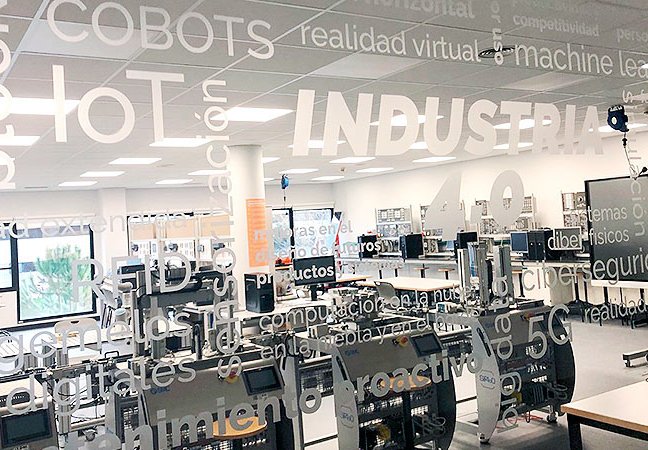

Cutting-edge laboratory for new technologies in the field of Industry 4.0, designed to train students from a practical point of view in all changes that have occurred in recent years in the world of industrial automation. Equipped with several working areas that represent different levels of automation and technologies, the Industry 4.0 laboratory is presented as a working space that combines different professions under a common concept within the framework of the 4th industrial revolution.

This laboratory is available for practicing industrial process control on the cloud, cybersecurity, programming different types of robots with and without computer vision, SCADAs, PLCs, HMI monitors, industrial network configuration, product control and management during production, digital twin, process data generation, adaptive manufacturing, IOT (internet of things), process simulation, smart conveyor belt, control and management of process energy consumption, creation and adaptation of electrical systems or different systems and types of sensors such as RFID (Radio Frequency Identification), and others, enabling students to learn and begin to develop their career with broad knowledge of different processes used today in the workplace.

All practice in this space can be framed within degree programs such as Industrial Systems Engineering, Biomedical Engineering and Industrial Organization Engineering, as well as different Master’s and Graduate programmes.

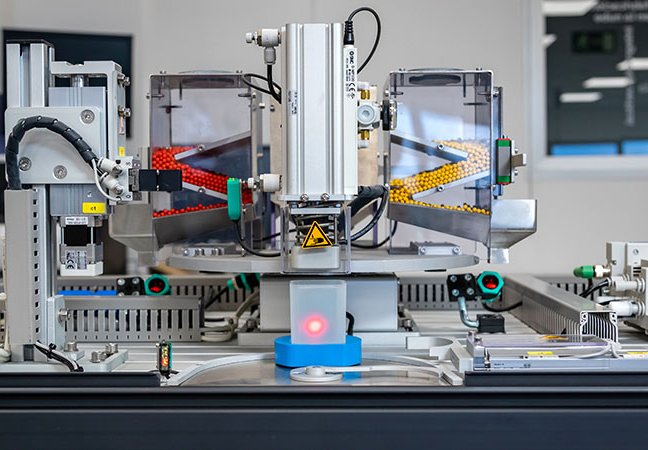

The Industry 4.0 laboratory has teaching systems such as:

- SMC industrial manufacturing processes simulation stations.

- Panels and trainers for adapting electrical signals and circuit studies.

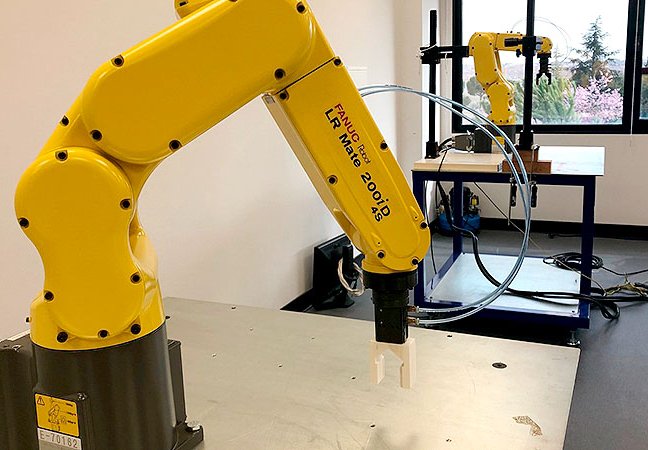

Practice is also conducted with latest-generation equipment online with equipment and systems currently in place in the workplace, such as:

- Fanuc robot with computer vision, ABB or Universal Robots collaborative robots (cobots).

- Siemens systems such as PLCs 1500, HMIs, RFID, IOT, Decentralized Peripherals, iCloud, Cybersecurity or digital twin.

- Beckhoff XTS conveyor belt.